Flash and JavaScript are required for this feature.

Download the video from iTunes U or the Internet Archive.

Description: This session continues on osteoporosis and covers bone structure related to evolution.

Instructor: Lorna Gibson

Lecture 12: Osteoporosis an...

The following content is provided under a Creative Commons license. Your support will help MIT OpenCourseWare continue to offer high quality educational resources for free. To make a donation or view additional materials from hundreds of MIT courses, visit MIT OpenCourseWare at ocw.mit.edu.

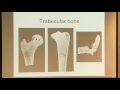

LORNA GIBSON: So last time we were talking about trabecular bone and that it's this porous kind of foam-like type of bone. And we talked a little bit about the modeling. And I think I got as far as starting to talk about osteoporosis. And I wanted to talk today about how we can model osteoporosis using those voronoi honeycombs that we talked about a while ago when we were talking about the structure.

So Bruno has a project on trabecular bone for the class. And he needed bone samples. And so we talked about different kind of bone samples we could get.

And the thing is if you get human bone-- well, there's all sorts of issues about just handling human bone and permissions, and it's complicated. So that was too complicated. We've used bovine bone before. You just go to the slaughterhouse and get bovine bone.

But one of the things with trabecular bone is because it grows in response to loads, the geometry of it can be different, sort of architecture can vary from one spot in the bone to another. And I have a colleague who started doing tests on whale bones, just because it's a way of getting nice, uniform bone.

So I was on a Ph.D. Committee a few years ago for a student who was in the Woods Hole program. She was at MIT, but was doing Woods Hole thing.

And I don't know if you've heard of the Atlantic right whales, the North Atlantic right whales. They're endangered. There's about 500 of them left in the world.

And they migrate between like typically the Bay of Fundy and off the Florida coast. So they go up and down the coast. And they sometimes get hit by ships. And then bones break and that kills them.

And her study was on ship impacts on right whales. And so I got to know people at Woods Hole who worked on whales. So Bruno, I called up my friend at Woods Hole. And the Woods Hole guy didn't have any bones. But he put me in touch with somebody at the Mass Fish and Wildlife Department. And he had a couple of whale vertebrae that he was willing to give up. So I got one of them for you.

So here it is. So I went out to the Mass Fish and Wildlife yesterday. And they produced this bone for me. I could either pass it around. It's not too heavy. Or you could come up and look afterwards. Shall I pass it around? Or do you want came up afterwards? Maybe come up-- pass it? OK.

So one of the things is our like vertebrae, there's these things that stick up like this. There's one that's missing off of this bone. There should have been one down here too.

But this is sort of what's called the body of the vertebrae. And in human vertebrae it's about that big.

But it's the same kind of general structure. There's these kind of bony plates that come off. And the body is almost all trabecular bone.

So you can see on this side, this is a growth plate here. But on this side, there normally would have been a thin shell of the cortical bone. And when I pass it around, if you look up at this point here, you can see there's just a little bit of that left. But it's kind of gotten worn out.

And the rest of this, if you look, you can see it's the trabecular bone. And you can see it's pretty uniform, which is why I thought this might be good for your tests. So I thought you should get in touch with Mike Tarkanian.

And I talked to him a little bit about cutting it with a water jet cutter. So I think we could use the water jet cutter. And I think I emailed you. If you could cut it in half, I'd like to have some pictures of it cut in half.

And he's got a diamond corer, cylindrical corer. So you could make little cylindrical specimens. And I know if you want to do compression tests or beams.

AUDIENCE: Well, I was planning to do compression tests.

LORNA GIBSON: Yeah, so you could probably use some kind of a bands or something to cut them up. So, and this is where the spinal column goes through in the whale. So there you have it. Anybody want to ask me anything about the whale bone? OK, so let me pass that around.

And I guess I have to tell you a couple of other stories. So while I was there, they have a brand new building. And it's all got solar panels and geothermal heat. And it's all very groovy.

And the guy who I was talking to about the bone, he wanted to give me a little tour of the building. And he said, oh, you've got to see your freezer.

OK, so the freezer. So he opens the freezer door. The freezer's like a room. And there's like a bear. I'm serious, like a bear on the floor, like a dead bear on the floor of the freezer.

And he said it was like a two-year-old bear that had, I guess, just come out of hibernation a couple weeks ago. I think it had gotten hit by a car or something. And somebody must have called them up. And they have it.

So they had this bear. They had like several deer. They had a coyote. They had like boxes full of all kinds of animals. So anyway it was kind interesting to see all these animals there.

And you know what he said about the deer? He said, normally deer in Massachusetts don't starve. Like if you live in the suburbs, you actually have a problem with deer eating your vegetable garden because there's deer all over the place.

But he said, this winter, you know how much snow we've had and how cold it's been? He said, deer have been starving this winter.

And I think a couple of the deer they'd had had actually starved to death. And people had called up. And they had come and kind of collected the carcasses. So anyway that was my little trip out to Mass Fish and Wildlife yesterday.

OK, so let's go back to talking about the bone. And I think last time we kind of left off more or less here. So this was a slide of what osteoporosis looks like.

And you can see the bone loss is a combination of thinning of the struts and resorption of the struts. And we wanted to try to model this, sort of an engineering sense. And the way we did that is we used our voronoi honeycombs.

So the bone has an irregular structure. And we wanted to look and see if we could model something that had an irregular structure. So we used the voronoi honeycomb.

And if you remember when we talked about the structure of cellular materials earlier on in the course, we said that these are generated by putting down random seed points and then drawing the perpendicular bisectors. And if you have a constraint that the seed points can't be closer than some exclusion distance, then you get structure where you have cells that are not all exactly the same size, but roughly the same size.

So that's what we did here. We got this structure here. And I had a graduate student, Matt Silva, who did a lot of these studies. And then he used this and analyzed it using finite element analysis.

So the first thing he did was he calculated the elastic moduli of the structure. So he applied loads. We calculated deformations. Figured out elastic moduli. And so this plot here shows a comparison between the analytical equations that we derived at the first part of the course and what he calculated for these voronoi honeycombs for the final element analysis.

So here's Young's modulus down here, for example. In the closed form, the line, that's just the analytical equation we had originally. And the little dashed line is his finite element. Here's the Shear modulus down here. And here's the possum's ratio up here.

So you can see, there's a pretty good agreement between these two things here. So let me write some of this on the board. And then I can keep going after that.

So for the 2D voronoi honeycomb, we have the random seed points. And we used the perpendicular bisectors. And we used a minimum separation distance between the points.

So we generated the structure. And then we did a finite element analysis. And from that, we calculated the modulus.

And what we found was the finite element analysis results were pretty close to our closed form analytical model.

And if we think about the modulus, the modulus is the average stiffness over the whole honeycomb. And when we look at the strengths next, the strength is going to be related to the weakest few struts. And we're going to find that the strength doesn't work quite the same way.

So first, we got the modulus. That's sort of the simplest thing to calculate. And then after that, we wanted to calculate the compressive strength. So we did a similar thing. We set up the voronoi honeycomb in the finite element analysis. We had a few more elements along the length of each strut.

And then we modeled the elastic buckling and the plastic failure behavior. And we looked at honeycombs that had different densities. And the lowest densities failed by buckling. And the higher densities failed by a sort of plastic yielding.

And we assumed that the cell walls were elastic, perfectly plastic. Remember we said if we have a material where-- this is for the solids-- so say this is the stress in the solid and that's the strain in the solid. If it behaves like that, we say that's elastic, perfectly plastic.

So we modeled the walls as elastic, perfectly plastic. And we made the ratio of the solid modulus to the yield strength similar to what it would be for bone, which is about 0.01.

And for that particular value, the transition between the elastic buckling and the plastic yielding failure was at a relative density of about 0.035. So then what we did was we analyzed structures that were a little lower than that were equal to that and then a little higher than that. So we would try and see what happened with these different failure modes.

And then we found that if we look at the compressive stress strain curve, this model here had a relative density of 15%. And the transition occurred at a relative density about 3.5%.

So this one here failed by a plastic failure. You can see, if we unload it, there's some plastic deformation. We get a little strange softening here, which is kind of characteristic of the plastic failure.

When we look at the overall deformation of the honeycomb, we saw local kind of failure, like we do in aluminum honeycombs. So that was the kind of stress strain curve for a relatively dense honeycomb that failed by yielding.

And then this is one for a much lower density. This is now point 1.5%. And this one fails by elastic buckling. And if we load it up and unload it, we recover most of the deformation.

Barry, do you think you could make that stop? Yeah.

AUDIENCE: There's a chance it could be--

LORNA GIBSON: Below. Just because we're recording it. It just doesn't seem very good.

OK, so what we did was we made five different voronoi honeycomb. So we had five sets of seed points. And we had five slightly different geometries. And then we averaged the results of those.

So if we make that calculation, this is the strength of the voronoi honeycomb here divided by the strength of the periodic regular hexagonal honeycomb. And this was plotted against relative density.

And you can see the strengths for the voronoi structure are a little bit lower than for the regular periodic hexagonal honeycomb. And they reach a minimum here. And the minimum's around about 0.05 relative density.

So this was the 1.5. That was a 3.5. That's 5% and 15%.

AUDIENCE: Why is there like a wide gap between 0.05 and--

LORNA GIBSON: Well, I think because we felt-- I think this one failed by some combination of-- there was a limit to how many of these we were going to do. And this is what we chose to do.

We wanted one that we knew was going to fail by plastic yielding. And that was this one. And we wanted one that we knew it was going to fail by elastic buckling. And we wanted a couple in between. So we didn't do-- I guess we were lazy is the real reason there's not another point in the middle there.

AUDIENCE: It just seems like there might be a variable--

LORNA GIBSON: You think it might go [CAREENING NOISE] like that. Except there's a physical reason why this happens. And I'm going to get to that in a minute. So let me I'll finish explaining this, and then I'll put the notes on the board.

So first of all, the strength is less than the regular hexagonal honeycomb. And then there's also this minimum here around about 5% density.

And I think the reason that the strength is not the same as in the voronoi in the periodic honeycomb is because if you look at the distribution of strains-- or you can think of the distribution of stresses-- so these were the normal strains at the nodes in the honeycombs. And the distribution here is for the voronoi honeycomb.

So the voronoi honeycomb, you have lots of members of different lengths. There are different orientations. And so there's some distribution of stresses and strains in each member. And that gives you the distribution.

In the regular hexagonal honeycomb, if you look at just the nodes, there's really just the vertical member, which has a certain strain. And all the vertical members are going to have the same strain at the nodes.

And then the obliques members, if you just look at the nodes, there's just going to be a maximum tension and a maximum compression at the nodes. Because there's a unit cell and it repeats, all the oblique ones are going to have the same maximum and the same minimum.

So the dashed lines here are for the regular hexagonal honeycomb. So the thing to observe here is that the voronoi has some strains and correspondingly some stresses that are outside the range of the regular periodic honeycomb. And so if there's parts of it that are seeing higher strains and higher stresses, it's going to fail at a lower load.

So I think it's this distribution because you've got this random structure, and you've got different lengths and different orientations of the members. So that's one reason why these strengths are less than the periodic structure.

I think there's a minimum here, because-- I think before the test I mentioned there's some interaction between elastic buckling and plastic yielding. And when you get that interaction, that also reduces the strength. And so there's a minimum near where the crossover is between the elastic buckling and the plastic yielding.

So let me write some notes of the compressive strength. So we'll say the cell wall-- so the cell wall elastic, perfectly plastic. And the yield strength relative to the modulus for the solid was 0.1, which is pretty much what it is for bone. And we assumed that the possum's ratio of the solid was 0.3.

And for this value of sigma Ys over Es, the transition between elastic buckling and plastic yielding is at about 3.5% relative density.

So then we made models with densities that were a little bit less than that and a little bit more than that.

And then the strengths we got from the voronoi were between about 0.6 and 0.8 times what we got from the periodic.

So then what we looked at were these maximum strains of the nodes. And we found that because the voronoi honeycomb had a much broader distribution of those strains, that led to the lower strengths.

And then we found the minimum strength was at a density of about 5%.

And if you think just about a pin ended column, and you make a plot of the strength-- so I'm just going to say the strength of that columm-- against l/r, the slenderness ratio. So say it's a cylinder, l would be the length. r would be the radius.

If you just had Euler buckling, you get a curve that looked like that. The Euler buckling load is pi squared EI over l. squared. So I goes as r to the 4th.

And if we get the stress, then it's going to be that divided by the area of the column. So it's pi squared E. Moment of inertia is pi r to the 4th over 4 l squared. And the area is pi r squared.

So it goes is as r over l squared, or 1 over l over r squared. So this would be the Euler buckling. So that's elastic buckling.

But at some point, the column is going to yield. If I make it really, really short, then it's going to yield before it buckles. And at some point, this would be the real stress here. And this would be failure by the plastic yielding.

And in practice, there's not like a sharp corner here. You know, if you made columns of progressively longer length, and you tested them, the little short ones would yield. So they'd be along here. But they don't kind of yield and the next one buckles. In fact, you get something like that.

So that when you're near that transition, when you're near this point here, the actual failure stress is a little bit less than that. And I think that's partly what's going on over there. It's the minimum.

OK, so those two studies, we just looked at the modeling and the strength of honeycombs. And we were kind of looking at how does the random structure change the properties. So the randomness of the structure didn't really change the modulus much at all. But it did affect the strength.

And then the next thing we did was we looked at putting defects into the bone. So we knew that the bone, partly the density is reduced by thinning of the struts and partly by resorption when there's a lot of density loss, a lot of bone loss. So we wanted to look at putting defects where we actually removed some of the struts.

So we did another series of voronoi models. So we did another series of tests where we looked at it if we have a certain density that we start with and then we look at losing the same bone mass or relative density in our honeycomb, and we look at what happens if we thin the struts versus if we remove struts.

So these plots here show that. And Matt Silva also did this. So this is the residual modulus plotted against the reduction in relative density.

So residual modulus is the modulus after we've reduced the density by some amount relative to the initial modulus. And if we have an intact honeycomb where we just thin the struts, we don't remove any of the struts, if we have an intact honeycomb, as you reduce the density, the modulus just goes down like that. So that's really just the same as those analytical formulas that we had.

But if you start removing struts, not too surprisingly, the modulus goes down substantially more. And at this value here, I think it was 30% or 35% density reduction, you reach what's called the percolation threshold. At the percolation threshold, you have two separate pieces of material. So obviously the mechanical properties are going to go down to zero when you reach that percolation threshold.

And then this plot over here is the same sort of thing, but now for strength. So it's the strength of the bone, or the strength of the honeycomb, after you've either thinned or resorbed the wall, divided by the strength of the intact honeycomb. And again, you're reducing the density here.

And this is for the intact model where you're just thinning the struts. And this is for the models where you're removing the struts.

So you can see that if you think of-- this is kind of a simple model, but if you think of the bone, if you first thin the struts, you're going to lose a little bit of strength. But then if you start removing the struts, you're going to lose a lot of strength. So that's really where people run into-- there's much higher risk of fracture once you get to the point where you might be resorbing struts.

OK, so let me see, what's next thing? OK, let me just finish the slides, and then I'll put the notes up.

So this is the same sort of thing, just plotting the strength and the modulus on the same plot. So you can see the shape of the curves is very similar. The modulus is a little bit more sensitive than the strength. And here we are thinning, and here we are removing the struts.

And then the next step was that we made a model that was more similar to bones. So let me write down the notes for this. And then we'll do that one that's more similar to bone.

Thought it didn't makes sense.

OK, so then we were interested in trying to model something that was a little closer to the structure of bone. And so we set up this model here. So we started with just a square voronoi. So you just force the points into a square, voronoi, or a square pattern, you get a square voronoi.

And then what we did is we just perturbed the points a little bit. And we got this perturbed voronoi array.

And so we made this model here. And we took a piece of vertebral bone. And we measured the angle of orientation of a lot of the struts. And we matched our voronoi model to that distribution in the bone.

So our model looked something like this. So you can kind of see how it's more or less vertical and horizontal, but not exactly. And here's a sort of comparison with a slice of vertebral bone. And again, because the loads are more or less vertical in the bone, the trabeculae tend to orient that way. And then have some horizontal struts.

So here you can see on the left, we've got a voronoi model that's more or less representative of the bone. And we've removed some of the struts.

So we're going to the same thing with this model. We thin the struts. And we remove the struts. And we try to see what the residual strength is. And you can see there's for of at least a 2d model this isn't a bad representation of the vertebral trabecular bone.

And this was the stress strain curve for both the specimen of the vertebral bone that was tested and then the honeycomb model that we made to kind of match it. So a similar kind of behavior.

This is how our model failed, this sort of a local band of struts that fail. Let's call it local deformation band.

And then what we did was we thought about changing the density. And what we did was we removed either horizontal or vertical struts, or we thinned either the vertical or the horizontal struts.

So these are the same kinds of plots as I showed before. This is the residual modulus. This is the residual strength. This is the density reduction.

And here we're reducing the density by making struts thinner. So it's still intact. We haven't removed any struts. But each of the struts gets thinner.

And this top line is for thinning the longitudinal or the vertical struts. And this was for thinning the transverse or horizontal struts. And then this is for removing struts here. So we're removing a bigger number. So the more we remove, the more the density changes.

And then this plot here is for the strength. So again, this is thinning. So we're moving either the horizontal or the vertical ones-- I'm sorry, thinning either the horizontal ones or the vertical ones.

And then this is for removing struts. And again removing more to reduce the density more.

So you can kind of see we're kind of working our way to more complex models here. So this one here was looking at the bone. Let me write some notes for this. And then we did a 3D voronoi model. So I'll do that one next.

Oop, over here.

So I'll just say the model was adapted to reflect the trabecular bones study in the vertebrae more.

So we perturb a square with array of seed points to get a structure that was more like the bone.

And then we looked at the reduction in the thickness and the number of strides in the longitudinal and transverse directions.

OK, and then the next model we did was the 3D version. So we made a same kind of thing. But with the 3D model, we had fewer cells in that model, because once it goes to 3D, you've got more struts in each cell.

But this was the same idea. We uniformly thinned the struts, or we removed the struts. And again, you can see removing the struts is a much bigger effect.

And also the other thing to look at here is for 3D the percolation threshold is 50%. So it kind of makes sense that if it's in 3D, and you've got struts in all directions, you're going to have to remove more of them. You're going to reduce the density more to break it into two separate pieces at the percolation threshold. So that was the 3D model there.

And then this is just a comparison of the 3D with the 2D for the modulus. We just did the modulus for the 3D structure because it sort of gets computationally more involved.

So the 3D, these two lines here corresponded to removing the struts and the change in the modulus. And the little triangles were the 3D voronoi calculation that we did. The little crosses here were the same sort of calculation done for tetratridecahedron. One of my former students had loaded that.

And then at the bottom here are the lines for the 2D structures, for either a regular hexagonal cell or for a 2D voronoi cell. And you can see, there's not a huge difference whether or not you take a regular structure or a voronoi random structure.

But there's a fairly significant difference between the 2D and the 3D. So the 3D, just you have to remove more material before you get the same reduction in modulus.

So let me write some notes for that.

So it's the same kind of analysis, but just with a 3D model.

So do you see the idea with these models? It was an attempt to look at a way that you could computationally estimate how much modulus loss or strength loss you get by either thinning the struts or removing the struts. So I gave you a way to model the osteoperotic bone. Yes.

AUDIENCE: Can you clarify the percolation threshold?

LORNA GIBSON: So the percolation threshold is say you have some network and you start removing things. If your remove enough, you have two separate pieces of things. If you remove enough struts, you have two separate pieces. That's called the percolation threshold. So I think it's-- you want to know why it's called that?

So I think that originated because it wasn't used in this kind of context. I think instead it was used in a context where imagine you have 2D plate. So you put 2D holes in it, little circular holes. And they we're looking at flow of a fluid through the plate.

So you can imagine, if you put enough holes, eventually they line up or they-- line up is not the right term-- but there's enough of them that they connect. And you end up with two separate. You have a path through for the fluid. That's called the percolation threshold. But in mechanics it's sort of two separate pieces. OK, does that makes sense?

So you know, at the percolation threshold, the stiffness is zero because you have two separate things and the strength is 0.

AUDIENCE: So the two doesn't have to be like separated by--

LORNA GIBSON: It could be-- yeah, yeah, it doesn't have to be a straight line.

AUDIENCE: Does it make a threshold between whether everything is interconnected?

LORNA GIBSON: Yes. Or there's some path that separates them. Yeah, that's what it is.

OK, so that's the end of the bit on osteoporosis. I had a couple more things I wanted to talk about on bone. So the next part is on the idea of using metal foams as a bone substitute materials.

So when they make hip implants-- so they're typically metals. They're titanium or stainless steel or something. Often what they do is they coat the outside with some sort of porous coating.

And the idea is the porous coating allows the bone to grow in. So you can kind of imagine, like especially on the stem and around the head of a femur, you'd like the bone to grow into that to attach. And having a porous coating helps.

And there's a couple of ways they do it currently. They use porous sintered beads. So they put little beads of metal on the outside. And the idea is that the bone grows into the little gaps between the beads.

Or sometimes if they have-- not so much for hip implants but sometimes when people have say car accidents and their face get sort of smashed up, and they have to have, say, a plate put in their face, and they need like a flatter plate, they use like a wire mesh. And they have sort of a wire mesh that goes on the outside. And it's the same thing. It's the idea to try to get the bone to grow into that plate.

So some people are thinking instead of using the porous sintered beads, or instead of using one of these wire mesh plates, that you could use metal foams. And so there's been some interest in using metal foams in coatings of implants.

And longer term, there's been some interest in trying to make sort of a vertebral body that would involve using a metal foam from the vertebral body. So you know that whale bone that we just passed around, that vetebral body, that cylindrical part, it's almost all trabecular bone.

So there's some interest in trying to use metal foams for spinal surgeries. Maybe not to replace the whole body. But to use in part of the surgery.

So I have a little slide here which shows a bunch of metal foams that people have made with the idea in mind that perhaps some of this could be used in orthopedic surgery. So these are some different kinds of metal foams. And these ones are made from titanium or tantalum.

So typically, the metals that they use in orthopedic implants are the cobalt chromium alloys. Titanium, they sometimes use tantalum or stainless steel. And they use those because they're biocompatible. And they're very corrosion resistant.

So these ones here are mostly titanium. And this is one that's a tantalum.

So let me just go over how they make them. And then I've got another slide that goes over it in more detail. And I'll write a few notes down.

So this guy on the top left up here, that's made by taking an open cell polyurethane foam, like a seating foam, like a cushion. And then what they do is they heat that up in an inert atmosphere, so that they are left just with the carbon. So it's a sort of vitreous carbon.

And then what they do is they coat that carbon by a CVD process with tantalum. And so they end up with a tantalum foam with a very thin layer of carbon at the core.

The carbon makes up something like 1% of the final composition and the tantalum is the 99%. So that's sort of a replica process there.

This one here is made by another replica process. They take an open cell polyurethane foam. They infiltrate it with a slurry, which has the titanium hydride particles in it. Remember when we talk about processing of the foams at the beginning, I said, if you heat up the titanium hydride, eventually the hydrogen would be driven off, and you'd be left with the titanium. So they do that, and then they sinter it, and they get a titanium foam.

This one is made by a fugitive phase process. So the idea with a fugitive phase is you burn off some phase. So you could mix powders, consolidate the powders, then you burn off one of the powders. And you're left with the other one. And then you need to sinter that together to make it have some reasonable mechanical properties.

This one here is made by using a foaming agent.

This one's made by expansion of argon gas. I think when we talked about the metal foams, we talked about the idea of packing, say, titanium powder in a can. And then you evaporate the can. And you then pressurize the can with argon gas.

And then you heat treat it. So you heat it up. And as you heat it up, the argon gas expands. And you're left with the pores.

This one's made by a freeze casting process. I have a slide. And I'll talk about that in a minute.

This one's made by a selective laser sensory. So it's like a 3D printing. But instead of printing in ink, this time you have a bed of a powder. And you've got a laser that selectively sinters.

So you turn the laser on and off. And where it's on, it's going to bind the material. When it's off, it's not going to bind the material. And then you raise the thing. You make a little bit more powder. You do it all over again. And you can get different patterns.

And then this is made by a sort of process in which they take powders and press them and ignite them. But I think that's not very commonly used.

So this is some more details about how they might do it. So this is the fugitive phase process here. You could take a titanium and a filler powder, pack them together. You know, you'd mix them up, pack them together.

You would raise it to a certain temperature to decompose the filler. So typically the filler decomposes at a lower temperature than what you sinter the powder, the metal powder that's left.

So you decompose the filler. You drive that off. And then you sinter the metal powder. And you're left with porous titanium.

This one's the expansion of the foaming agent. So you take your titanium powder. You might have a binder and then a foaming agent. Mix those all together.

They heat them up until typically the binder becomes a liquid. And the foam foams up the liquid binder. Then they drive off the binder. And then they sinter at a higher temperature the titanium. So you you've got a porous titanium left.

This is the freeze casting or the freeze drying process. So here they would take titanium powder and put it in agar. And the agar's in water. So the agar is like a jelly, like a gel. But it's mostly water.

And then if you freeze it, what happens is the water freezes. And it drives off the titanium agar into the interstitial zones between the frozen ice crystals. So these little dots here are the ice crystals. The ice crystals are growing as it gets colder. And as the ice crystals get bigger and bigger, you're left with the titanium and the agar in between those ice crystals.

And then if you sublimate the ice off, you're left with a porous thing. And you can sinter the titanium if you want to make it a little more dense.

And this is a rapid prototyping thing here. So you spread the powder. You could either print a binder or you could use a laser to sort of almost weld the particles together.

Then you would drop the piston, put more powder down, have the binder go again until you made your product. And then you would get rid of all the unbound material. And you'd have your final product.

OK, so these are some of the methods they can use for making metal foams. I don't know, should I write notes? Or are you good if I just put the notes on the website? I'll put the notes on the website.

And then this is a stress strain curve for a titanium foam. So it looks like all these other kinds of foams and bone and wood and everything else that we've looked at.

And this is some data for titanium foams that are made by different processes. And we've just taken different data from the literature and put it together.

So this is the modulus here. This is a slope of 2. You can see some of the data is sort of near that slope, but below it. And there is obviously a large spread in the data too.

But if you go back and look at the different types of structures, then not all these have this kind of typical foam-like structures. The structures aren't all quite like a foam either. Yeah?

AUDIENCE: So is there any objective in this to make the foam similar in structure to the bone that will be growing into it? Or does it just need to be scaffolding?

LORNA GIBSON: I think for this, they just want to make a porous thing. And they're thinking about coatings. So the coatings aren't necessarily similar to the bone.

When we finish the section on bone, we're going to start talking, I think, about tissue engineering. And when we talk about tissue engineering, people have made scaffolds to try to make them the same shape as the anatomical part that they're trying to mimic. And then they make a cellular kind of core. So they have made some more of an attempt to do that.

I could give you a sneak preview. Would you like a preview?

So these are some scaffolds that are generated from a making different kinds of tissue. These aren't all from bone.

But this one here, for example, is for regenerating bone. And they've printed it in this exact geometry, because that's going to replace some anatomical piece. And they want it in that geometry.

So I'll talk more about that. But so for the scaffolds, they sometimes do that. But not so much for these bone coatings.

Let's see. Se we did that. We did that.

So these are the data. And then over here, there's the compressive strength. And again, you know, this is our line with a slope of 3/2. Again, there's a lot of scatter, because there's a lot of variation in the structure of these things. But it's in the ballpark.

So are we good with metal foams? And there's just like a page and a half of little notes. Should I just put that on the website? You're good? OK.

OK, so the last topic I wanted to talk about on bone has to do with how people look at the structure of bone in evolution and in evolutionary studies. So the idea here is, in particular in looking at sort of pre-human species, sort of hominid species, people are interested in when primates went from being quadruplets to bipeds.

So obviously, bipedalism, walking on two legs, is characteristic of us. And people would like to know if they find some fossil-- you can't just tell from the fossil directly is it a biped or a quadraped. You can't see the species moving because it doesn't exist anymore. So you'd like to have some way of making some estimate of whether or not it was a biped or a quadruped.

Let me get my notes together here.

So I wanted to kind of look at the big picture a little bit and look at the evolution of different species. And this is a phylogenetic sort of chart. And this is kind of-- have you heard of the tree of life? This is like the tree of life.

So this piece of it is-- metazoa is for animals. So not plants, animals.

And this goes back about 1.2 billion years. So these are millions of years ago. And then these are different sort of eras and ages that are defined.

And when we have a branch here, this is a common ancestor. And then this is a branch in one direction, and that's a branch in another direction. So these points here, like 1 and 2 and so on, the implication there is that there was a common ancestor to everything that traces back to there.

So this point here, 1, is 1.2 billion years ago. So this was sort of very early kind of species.

And the very first things were, well, multicellular things. I mean, there were little amoeba type things. But the more sort of sophisticated animals were sponges.

And there's three kind of classes of the sponges. There's calcarea. And they're called calcarea because they're mineralized. And they're mineralized with a calcium carbonate.

And then there's another branch of them called-- I don't know if I'm going to say this right, but hexactinellida. And those have glass. Those are called glass sponges because they have SiO2 is the mineral in those.

And then there's these guys here the demospongiae. I think some of those have calcium carbonate and some of them don't. Oh, no, some of them have silica. And some of them don't.

So these things here are sort of very early multicellular structures. And the mineral in them is either calcium carbonate or silica.

And then if we move up, I've sort of highlighted a few of them. The cnideria-- I know there's a C, but that's actually-- when I say s-nideria, my biologist friends laugh at me. And they say no, no, no, it's nideria.

The cnideria are the corals and the jellyfish. And corals are also mineralized with calcium carbonate. And you can see they branched off something like a billion years ago.

Then we get up here. These are the mollusks. So the mollusks are things like bivalves, like if you like to eat claims, things like that. So bivalves, snails, and things like octopi, octopus. So those are all molluscs. And molluscs, when they're mineralized, also are calcium carbonate. So those are the calcium carbonate kind of shell.

So we haven't got up to anything bony yet. Bone is collagen plus a calcium phosphate. So we haven't gotten to anything that's a calcium phosphate yet.

Then another large class is arthropoda. That's insects and spiders and crustaceans. Those all have a chiton skeleton. So if you think of like the exoskeleton of an insect or a spider, those are chiton.

And crustaceans, things like lobsters, those also have a chiton shell. And in crustaceans, it might be mineralized. But again, the mineral is a calcium carbonate.

So all the way up here, most of these things, if there is any mineral, it's calcium carbonate. And if we get up finally to the vertebraes, the vertebraes have the calcium phosphate and have a bone, like what we think of as real bone. So the vertebrates obviously involve things like mammals, birds, snakes, and fish.

So this is kind of the big picture going back. And sort of one of the interesting things is that bone doesn't come along until you get somewhere over here.

And I have one more little, nice slide here. So when I talked about the sponges, they were these guys here with the glass sponges. Joanna Aizenberg at Harvard did a nice study on glass sponges. And she looked at this one here. It's called the Venus flower basket is kind of the common name. And it has this hierarchical structure. And it's remarkably stiff and tough.

And what she did in her paper was look at optical and mechanical properties. But they looked at the structure at different length scales. So there's kind of a cellular structure at this length scale. It's kind of a tube. This was just a picture I took in a natural history museum.

But if you look at higher magnification, each little strut is made up of sort of fibers and has a hierarchical structure itself. So that's just one of the sponges.

And here's a similar chart for the vertebrates. So this point here is where the other chart kind of branched off.

And if we start with the earliest things again, the earliest ones with the most common ancestor back here is something called cyclostomata. And those are things like jawless fish, so things like lamprey and hagfish.

Do you know what a hagfish is? It's this kind of eely thing. And I have the video for you if you don't know what a hagfish is. So let me get out of here because it's just an amazing thing, the hagfish.

OK, so let's see, I got my sound on.

[VIDEO PLAYBACK]

REPORTER: Here, at the University of Guelph, about an hour outside Toronto, materials scientist Atsuko Negishi and biologist Julia Herr think that these lovely creatures, called hagfish, may revolutionize how we make strong materials.

ATSUKO NEGISHI: These are specific hagfish. They're well known for their unique defense mechanism.

REPORTER: So if I wanted to see this, what would we do? Like could we poke at it with a stick?

JULIA HERR: I think the best way to do it is to reach in there and grab one.

REPORTER: Oh, my gosh, look at that disgusting-- oh, no, I've been slimed. I feel like an outtake from Ghostbusters. Look at the quantities of this stuff.

[END PLAYBACK]

LORNA GIBSON: He used to do this for The New York Times. And I think he's got his own going on, but he used to make these little videos. And he had a show on PBS a year or two ago all about materials. And there were like four different episodes.

And he talked about different kinds of materials. And he went to different labs. But he's quite a character.

But anyway the hagfish have this defense mechanism where they make the slime. And I don't know if you know Professor McKinley over in mechanical engineering here at MIT, but he collaborates with those people of Guelph. And he studies what he calls non-Newtonian fluids. Well, a lot of people call non-Newtonian fluids.

A Newtonian fluid is a thing like water, where the viscosity is a constant no matter what sort of strain rate you shear it at. And a non-Newtonian fluid does not have that property. The viscosity changes. And some of them have a strength, like in the hagfish one has a strength.

So Gareth's studies things like this kind of hagfish slime. I don't know if he still has them. He used to have hagfish in his lab over him building, whatever it is, 1 or 3 or something over there.

OK, so that's what the hagfish are, just because that's amusing. And they don't have bone. So they and the jawless fish don't have bone, even though they're called vertebrates.

Then the next sort of most recent thing is the chondrocytes. Those are the cartilaginous fish, so things like shark. So sharks don't actually have bones. They have cartilage. And they have a little bit of mineralization in the cartilage, but they don't actually have bone.

And the first thing that actually has a bone is the ray finned fish, which are these guys here. And that occurred about 450 million years ago.

And then everything in the vertebrate since then is bony. So there's coelacanth-- I don't know if you've ever see those. Every now and then they find one of these things in Florida or something-- lung fish.

There's these guys here, which are the frogs and the toads and the salamanders. So it's finally getting to be spring after the winter from hell. And the salamanders are going to come out into the vernal pools and mate. And it's cute. So anyway, they come out this time of year.

And then there's the amniota, things that have eggs of one sort or another. So that includes us, the mammals, the birds, the snakes, and the turtles. And so those would have branched off about there.

So the last thing I wanted to point out here is that there's this huge kind of diversity of animals that have evolved over millions and millions of years. And that the first ones that were mineralized used the calcium carbonate and that the bony type materials didn't really evolve or didn't appear until about 450 million years ago.

And then these are the vertebrates that have these kind of bony things.

So as I've said many times now, the bone grows in response to loads. And the bone structure reflects the mechanical loads and the function. And evolutionary studies have looked at both cortical bone and trabecular bone architecture to try to say something about the locomotion of the animal or of the species.

So there's ones that look at cortical bone. But I'm just going to talk about one that deals with trabecular bone.

So this study was done by a group of peoples, the first author was Rook. And what they studied was the ileum. So this is a pelvis. And there's the ileum is one of the bones in the pelvis.

And they found fossils of a hominid species that was about 8 million years old, called Oreopithecus bambolii. And bambolii refers to the place in Italy where these fossils were found.

And so they found two-- or at least somebody found two pieces of an ilium. And they took x-rays. And they made a digital reconstruction so that they would get one ilium-- it turned out that the two pieces were two different parts-- so they could make a whole one out of the two pieces.

And then they looked at the structure of the trabecular bone. And they compared that structure to the structure of the trabecular bone in humans and other primates. And they wanted to see is it more like the humans, which are obviously biped, or is it more like some of the primates, which are quadrupeds.

So this just shows for a human and a non-human primate what the structure of the ilium is. And these little black boxes with the letters are what are called anatomical landmarks. So they're sort of comparable spots on the bone of different species. And what they were doing was looking at the trabecular architecture at these different spots. So you can kind of see how they're more or less analogous in the two different species.

And this is the digitally reconstructed ilium that they put together from their fossil species. And again, these little letters refer to these anatomical landmarks.

And then what they did was they compared the Oreopithicus, the fossil, with the human and then three non-human primates. So these four images are all from the fossil. These are the human. These are champi, siamang and baboon.

And this square here corresponds to that one there. This is B, corresponds to that one. And C and D are those two there.

So they had two fossils, they made the digital reconstruction. They looked at certain areas. And then they looked at the same or analogous areas in these other species. And they tried to look for similarities and differences in the bone structure.

So let's look at this first box A. You can see there's a very white bit here. And the white corresponds to more dense. So there's a white bit that's more dense in their fossil.

And in the human bone, you see is a similar sort of band right there. And if you look at the other non-human primates, that band is missing.

So that says to them, OK, this feature, this one feature at least, is more similar to the-- sorry, in the fossil here is more similar to the human than it is to the non-human primates.

And then they had three other landmarks that they looked at like that. So this one here again is a sort of dense regions. So you can see that white dense region. There's some there. There's some here. So those are the fossil and the human.

But there's a teeny bit here and a teeny bit there. But it's not as pronounced in the non-human primates. Yes.

AUDIENCE: From I get at least so far, the portions of the bone that are dense versus not dense seem less relevant to the direction of loading than the orientation of the foamy parts of the trabecular bone.

LORNA GIBSON: So the density reflects more or less the magnitude of the stresses. So if the stresses are higher, it's going to be denser. And the orientation of the bone, like whether or not which way the struts are oriented, that reflects the sort of ratio of the principal stresses.

So if the principal stresses go in a certain direction, the bone's going to tend to line up in that direction. That's what that Guinea fowl study was kind of about. OK? Are we good? OK.

And then these other two, so in B-- and you can't really see it from here, but they looked at the sort of architecture of the trabecular bone. And they said that it was more similar in the fossil in the human than it was in these other three primates.

And this region here, this looks very similar to that bit there to me. But I think there was some other feature about this region that they were looking at. And again, it was more similar to the human than it was to the non-human primates.

So by just looking at the pattern of the bone and the density of the bone and comparing it to these other species, they said that the-- and you know the hip, because we're standing like this, you would kind of expect to see differences in the hip. That's why they wanted to look at the ilium.

So the conclusion they made was that these observations suggested that the species was bipedal, or at least spent some of its time as a bipedal animal.

And I think that might be it. Do I have more I have one little summary here.

So just to summarize what we've done on bone this week. We talked about the structure of the bone. We talked about mechanical properties in the foam models. We talked about osteoporosis in the voronoi models, how you can try to represent the loss of bone and the loss of bone strength using those models. We talked just a little bit about the idea of using metal foams as bone substitutes or coatings as implants, and then this little bit on trabecular architecture and evolutionary studies.

I have some notes, but I think we've got just a couple minutes left. So maybe I'll just scan those and put them on the website? Are we good with that?

AUDIENCE: I have a question about what we just looked at about the different species. We always consider on the density changes. Can there always be changes in the solids?

LORNA GIBSON: So it changes a little bit from one species to another. So the question is, does the solid properties of the bone, the solid bone itself change? So if you look at cortical bone in different species, it changes a little bit, but like 10%, not a huge amount.

So the two most common things people have compared are bovine bone and human bone. And there is a slight difference between them. But it's not a huge difference.

One of the other things people have looked at in osteoporosis that I didn't really talk about was there's another whole set of things that can go on that reflect what you're talking about. So they talk about bone quality as well.

And when they talk about bone quality, they're talking about are there micro cracks in the solid. So you might imagine as you get older, it's not just that you lose the struts or that the struts get thinner, but the solid bit itself has more cracks in it.

So you can imagine if the solid bone itself had little micro cracks, then it too would be weaker. And then you think what I put up was bad. It gets even worse if you put that in as well.

So, yes, people do look at bone quality, which is sort of looking at with age. And typically it's fairly elderly people that the bone quality is an issue. I guess there are certain diseases where it's an issue. But in osteoporosis, it's sort of elderly people.

Any thing else? Should I stop there for today?

So there were hardly any equations in this. Did you know that? So we got to the part where there's lots of equations.

So next week I'm going to talk about tissue engineering. I think I'm going to talk a little bit about different kinds of scaffolds, how they make scaffolds, how the scaffolds fit sort of into an anatomical things, what is that supposed to represent, how they use them clinically a little bit.

And we had a research project on osteochondrol scaffold, so scaffolds for replacing bone and cartilage. And I'm going to talk a little bit about that as sort of a case study in tissue engineering scaffolds.

And I have some stuff on cell mechanics and how biological cells interact with scaffold. I don't if we're going to get to that next week or not, but somewhere close to that.

So the next bit is on tissue engineering scaffolds, osteochondrol scaffolds, cell mechanics. And there's not that many equations in that part either. So OK.

Free Downloads

Video

- iTunes U (MP4 - 155MB)

- Internet Archive (MP4 - 155MB)

Subtitle

- English - US (SRT)